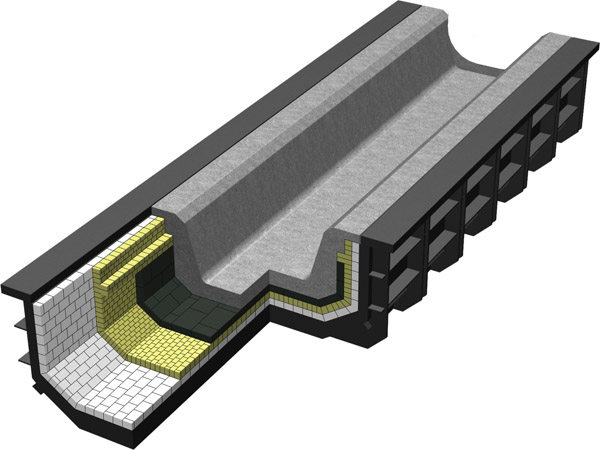

| 產品簡介 | 高爐流道耐火材料 |

本公司開發製造之高爐及電弧爐澆鑄材具有下列特性:

本公司並以澆注材料預鑄電弧爐用出鋼槽供客戶選擇使用。

|

|

■ Slag & Iron Zone:SBC-M81、SBC-M82、BFR-MTA、BFR-MTH

■ Safety Lining:MRL-75L

■ Repairing:MT-RG2、SPNG-TS1、SPNG-TM2

Specification

Brand |

SNC-M81 |

SNC-M82 |

SNC-B20 |

SNC-B17 |

|

Properties |

|||||

After heat treatment for 3 hours at 1450℃ |

Modulus of Rupture (Kg/cm2) |

≧50 |

≧70 |

≧65 |

≧100 |

Bulk Density (g/cm3) |

≧2.80 |

≧2.80 |

≧2.70 |

≧2.82 |

|

Chemical Composition (%) |

Al2O3 |

≧65 |

≧55 |

≧65 |

≧75 |

F.C. +SiC |

≧20 |

≧35 |

≧10 |

≧13 |

|

MgO |

-- |

-- |

≧10 |

-- |

|

Characteristics |

Casting |

Casting |

Casting |

Casting |

|

Application |

Slag & Iron Zone of Main-Trough |

Slag Zone of Main-Trough |

Iron Zone of Main-Trough |

Iron Runner |

|

Brand |

BFR-MTA |

BFR-MTH |

MT-RG2 |

SPNG-TS1 |

SPNG-TMZ |

MRL-75L |

|

Properties |

|||||||

After heat treatment for 3 hours at 1450℃ |

Modulus of Rupture (Kg/cm2) |

≧29 |

≧25 |

≧10 |

≧50 |

≧50 |

≧800 |

Bulk Density (g/cm3) |

≧2.50 |

≧2.50 |

≧2.20 |

≧2.80 |

≧2.85 |

≧2.50 |

|

Chemical Composition (%) |

Al2O3 |

≧60 |

≧60 |

≧60 |

≧52 |

≧65 |

≧72 |

F.C. +SiC |

≧20.5 |

≧23 |

≧22 |

≧30 |

≧10 |

-- |

|

MgO |

-- |

-- |

-- |

-- |

≧5 |

---- |

|

Characteristics |

Ramming |

Ramming |

Gunning |

Wet-gunning |

Wet-gunning |

Brick |

|

Application |

Iron Zone of Main-Trough |

Slag Zone of Main-Trough |

Repairing |

Slag Zone of Main-Trough |

Iron Zone of Main-Trough |

Safety Zone |

|